Printing Just Got Better: Things to Consider When 3D Printing with PETG Filament

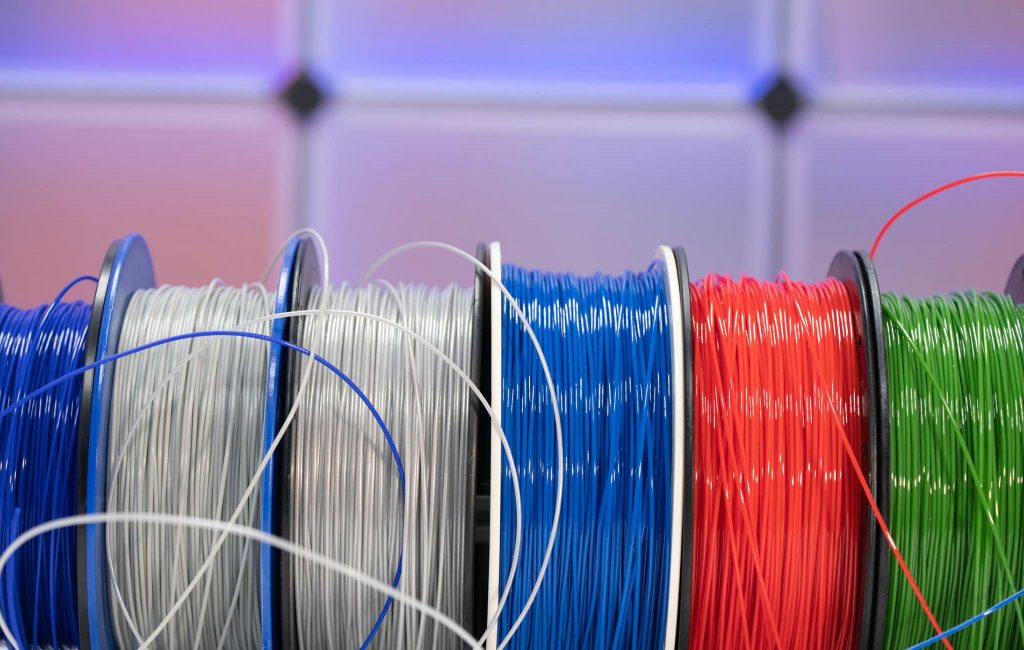

Because of its amazing colour options, mechanical strength, heat resistance, and ease of printing, PETG short for Polyethylene Terephthalate Glycol, a thermoplastic polyester, has become a very popular material for 3D printing. It is a variant of Polyethylene Terephthalate (PET), a common type of plastic used in many consumer products, including food and beverage containers.

Contents

List of Things to Consider When Picking a PETG Filament for Printing

Anytime you need a next-level option for 3D printing, get impressive tensile strength and durability by utilising strong, durable and highly resistant filaments PETG for 100% satisfaction guarantee. However, before picking one, there is a list of things to consider to make sure you have made the right choice for your printing needs.

PETG Properties

PETG is a popular material choice for FFF 3D printing because of its properties. The greater melting temperature of filament PETG for 3D printing-typically between 220 and 260°C. When compared to PLA, this is one of its primary advantages. It is more suited for items that must endure higher temperatures due to its higher melting point.

Additionally, PETG filament has solid mechanical qualities that make it fairly sturdy and long-lasting. Its tensile strength is approximately 50 MPa, which is a little less than that of PLA. But unlike PLA, PETG is more flexible, which makes it less brittle and more impact resistant. And, because of its strength and flexibility, it is a well-liked material for mechanical and functional parts as well.

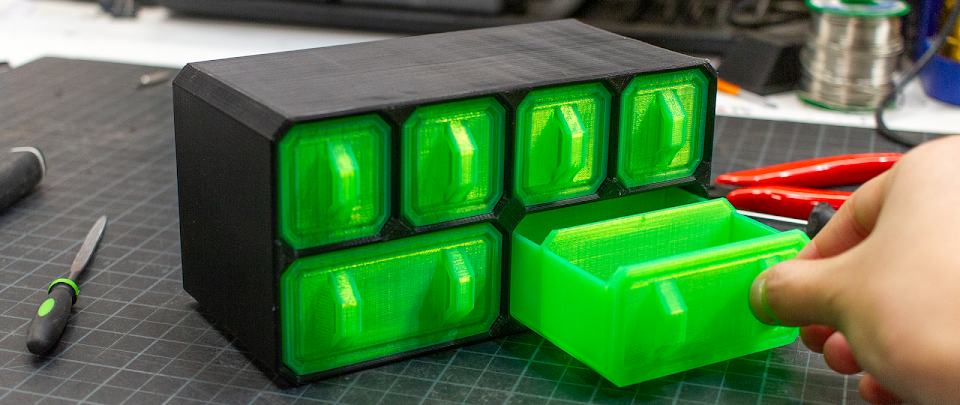

It possesses outstanding layer adhesion, which means that a 3D print’s layers adhere to one another well. As a result, prints have a high level of structural integrity and have fewer failures because of separated layers. Transparency is one of PETG’s key features. It is a suitable option for prints when some degree of transparency is required as, although it is not entirely clear, it is more transparent than the majority of other 3D printing materials.

Lastly, the filaments PETG are appropriate for outdoor applications due to the material’s resistance to water and UV rays. While it’s resistant to a wide range of chemicals, it should be noted that not all conditions are appropriate for using it because some solvents can cause damage to the material.

Besides its many benefits, the material also comes with some drawbacks. Compared to PLA, it is more challenging to print with, necessitating precise printer calibration and frequently a heated print bed. Additionally, it is more likely to ooze and string, a phenomenon in which extra material is left behind when the print head moves. However, with the right settings and some practice, these issues can be minimised.

Uses

In the realm of 3D printing, the development of working prototypes is one of PETG’s main uses. It is appropriate for creating prototypes that need to be durable and have some degree of heat resistance due to its balanced mechanical qualities and capacity to tolerate higher temperatures. Before starting mass production, engineers and designers commonly use filaments PETG to build prototypes that require a higher level of toughness and resilience.

Furthermore, PETG is widely used in the production of consumer goods, particularly those that require chemical resistance and durability, like protective casings, mechanical parts, and containers. It is a favoured option for products meant for extended use due to its ability to tolerate mild impacts and chemical resistance.

Hardware Requirements

Given the numerous changes in the PETG formula, it is challenging to say with certainty what temperature to print at. Certain additives cause the printing temperature to drop noticeably, while others cause the temperature to rise noticeably. To get the best print quality for you, start at 245°C and experiment with 5°C higher or lower.

A hotend lined with PTFE Teflon is used in some 3D printers because it is simpler to produce than one that is made entirely of metal, from the heat sink to the nozzle. Some 3D printers may be able to use lower-temperature PETG filaments, with an optimal temperature of 240°C or less because PETG prints just at the temperature where PTFE starts to break down. PETG generally requires an all-metal hot-end to fully tune your filament; that is, although prints may be successful at 240°C, full strength is not achieved until 255°C.

Also, make sure your heated bed is adjusted to 65°C for the highest possibility of success. Higher temperatures might be necessary to give some PETG enough adherence to the bed since they are more likely to distort than other PETG. If you’re having difficulty, bump the temperature up by 5°C at a time until adhesion improves.

On the other hand, to get an excellent first layer, you can apply a wide range of 3D printer adhesives to the bed of your printer in addition to building surface enhancements. Since these adhesives were created especially for the 3D printing sector, you can be sure they have been tried and tested as reliable 3D printer adhesives.

No Comments